Robotic Technology Improves Efficiency

Creating a prosthetic or orthotic device is both a mix of art and science.

Did you know that a robot may be helping to create your device? Our practitioners create devices with expert skill and experience. Each patient brings a unique challenge for a practitioner to address. As masters of their craft, practitioners use a variety of methods and tools to provide the best solution for every individual patient they treat. At WCBL, we utilize both steadfast traditional methods as well as the latest technology. To begin the process, a physician prescribes a prosthesis or orthosis. Next, the patient visits a prosthetic or orthotic practitioner. The practitioner then works with the patient to determine the best device for their needs.

Some parts of a device are custom-made, though many parts are manufactured by an outside source and sent to us for assembly at our facility. Accuracy and attention to detail are most important in the manufacturing process. Our goal is always to create a device as comfortable and useful as possible. Regardless of the method used, all practitioners begin with an impression (or mold) of the limb being treated, either by a casting or digital reading.

In the O & P world, hand casting has always been the gold standard. However, new technology has begun to change that.

Traditionally, an orthotist or prosthetist takes a plaster hand casting of the limb to create a device. Next, plaster fills the cast to create an exact replica of the treatment area. After it is dry, a technician uses the plaster mold to build the device and achieve a perfect fit. This can be a lengthy process. The patient often returns for multiple fittings and device adjustments. However, at WCBL, we also utilize the latest technology to dramatically decrease the time spent creating each device.

A CAD CAM scanner allows our team to produce a higher volume of devices, at a higher rate of efficiency.

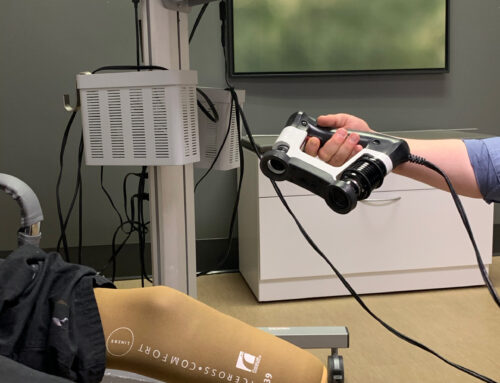

A practitioner uses a hand-held laser scanner, specially developed for the fabrication of orthoses and prostheses to obtain a digital measurement. A CAD CAM (computer-aided design and computer-aided manufacturing) software program receives the digital scan. The measurements are then used to make a mold of the treatment area. Afterwards, technicians enter digital scans of the patient into the machine.

Next, the CAD CAM uses an Ortis 7-axis carving system to whittle down foam pieces into exact replicas of the scan. This process takes an average of 30 minutes. Technicians then build the device directly from the foam mold.

- CAD CAM software.

- Foam Block inserted into Robot Carver

- Foam block carved into shape of prosthetic socket

- Final Result – Prosthetic socket

Unlike many facilities, at WCBL we have an on-site state-of-the-art fabrication lab.

Technicians in our lab create our devices on-site, thus providing a quick turn around time and the best quality. WCBL technicians are highly talented and skilled with decades of experience between them.

Our 7-axis robotic carver provides fast and accurate production of our devices. It carves most prosthetic and orthotic molds in 5-20 minutes with 0.1mm accuracy for a smooth finish on the most complex shapes. As a result, we are able to provide our patients with the most accurate fit and best turn-around time possible.

The CAD CAM scanner and carver are unique equipment that very few facilities have access to. Because of this, we are very excited to be able to offer this cutting-edge technology to our patients. WCBL President & Owner, Greg Bauer says “The investment we have made in our ORTIS Robot Carver is not just a benefit to our company, it is a huge benefit to our patients. We can now quickly and easily carve any 3D shape. The robot uses a simple interface and has a small footprint, allowing us to increase the speed and quality of our orthotic and prosthetic production. Instead of making one brace every few hours, we now make several per hour. This robot has power and speed! It has also made it possible for us to use our CAD CAM scanner in the most productive way possible.”